3D printer resin is one of the three basic forms of 3d printing material used by 3D printers. It always 3D prints parts with far superior surface finish, details, and dimensional accuracy than all types of FMD printers. It also 3D prints parts with very low mechanical properties and are usually very easily breakable.

Resin printing is considered to be more expensive than FMD printing as material and their specific 3D printers are much more expensive than most FDM printers and FDM printing material. This article is all about understanding the basics of resin 3D printing. It’s about the material, its shelf life, types of resin available, applications, and how to select the best resin material.

What is Printer Resin?

Resin is a kind of plastic but it is more than a generic plastic. Normal forms of plastics can get cracked and wrapped easily but resin material 3D printed does not wrap easily. Resins are made such that they can uphold temperatures between -40°C to 140°C. Resin materials have incredible resistance against extremely low temperatures that generally impact common forms of polymers. Opposite to plastics, resins do not absorb moisture from air or surroundings that prevents water damage.

What is Printer Resin made of?

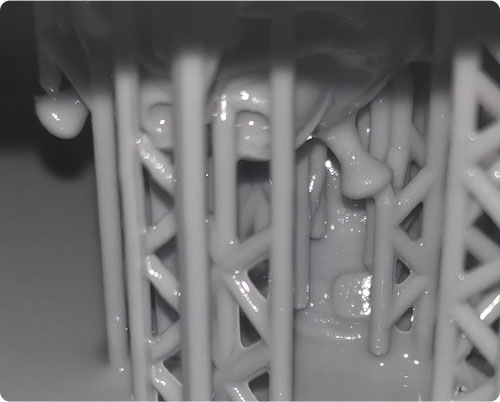

Resin is made up of liquid plastics that can be cured with ultraviolet rays. It is a photosensitive material used in 3D printing. It is processed by laser light of ultraviolet frequency within the 3D printer and thus transmuted into a solid form.

Plastics are usually a mixture of monomers (molecules that react across each other to form a polymer chain) and oligomers (molecules that consist of repeating monomers molecules). Light energy is used to destroy the ends of monomers and oligomers which enables their ability to be attached. This leads us to the process of formation of a plastic material called Resin.

How long does Printer Resin last?

A 3D printer resin can last for 365 days or a year. It’s still possible for a 3D print with resin to surpass its expected life, but the quality of the print will not be the same or as good as when it was first purchased.

To increase its life beyond a certain time, a resin must be kept in a cool and dark area. Resin is designed to be kept on shelves for most of its use, but if you don’t pay attention to these factors, the life of printer resin will be reduced significantly. There’s a reason for keeping resin in bottles that block UV light.

Types of Printer resin available

Standard Printer Resin

Standard Resin is a kind of transparent material with a yellowish tint that is obtained or produced by hardening a liquid resin through a laser process. It provides great surface quality with a high level of detail at a very low cost. Because of its low strength and resistance against stress, the freedom of design is limited.

ABS-like Printer Resin

ABS-like resin holds most of the mechanical properties of ABS plastic. ABS (Acrylonitrile Butadiene Styrene) plastic is a milky thermoplastic (the way material responds to temperature) polymer. ABS plastic can be heated and cooled several times without any degradation. So, ABS-like resin has phenomenal tensile strength, bending strength, hardness, and great toughness. It is suitable for objects where high tensile and stress strength are required.

Water Washable Printer Resin

As many of the resin can be washed away or trashed by using alcohol or other carbonated substances. But water washable resins can be cleaned using water. They usually have low strength but they are cost-effective and are considered efficient printing materials.

Printer Resin Applications

The properties of a particular resin define its need for a specific application. But with the passage of time and evolution in manufacturing techniques, industries have produced resins from different polymers that have certain properties to overcome numerous challenges in different fields. But the majority of the applications demand resins that have a great surface finish.

Due to their dominance over typical plastic, resins are the perfect solution for high-accuracy 3D prints. For manufacturing molds such as prototypes or aesthetic parts etc., resins can be used. Few non-functional prototypes, decorative parts, and parts that require more details and complex geometries, resins are particularly adapted. New and scientifically enhanced resins can provide better surface quality and finish.

Resins with high resistance and rigidity are also available in the market. Resins can also be used to manufacture transparent and translucent surfaces for storage and enclosure devices. Resins are also widely used in jewelry, engineering products, and medical applications.

How to select the best Printer Resin?

Choosing the best printer resin can be a very difficult decision due to its wide range of applications. But here are a few important points that may help you to narrow down your choice.

Quality of Finish

Certain resins will produce prints with a smoother surface than other competitive 3D printer resins available in the market. You should gather every possible information available about the resins and look for those that give high accuracy and lower shrinkage after printing. A high-quality print requires a better surface finish.

Durability

Durability is another important property of a printer resin and hence a print should not be very brittle or prone to breaking. If you need a tougher print with great resistance against stress, there are resins in the market that have been processed to enhance their toughness. Such resins have high tensile strength and elasticity which makes them perfect for making functional joints and tougher prints.

Transparency

If you desire your product to be transparent or translucent, you will have to go for special resins that are made to produce transparent objects or parts. There is not much difference between standard resins and those that create transparent prints but they can produce a clearer surface to give a glass-like look. The process of manufacturing such surfaces can take longer periods in comparison to other simpler objects.

Biocompatibility

A valid reason that many manufacturers use SLA (stereolithography) printing for medical equipment and prosthetic devices is that these methods have been used to create orthopedic implants, splints, dental retainers, etc. You must use a particular type of resin that can maintain its chemical and structural stability. Such resins can stay in contact with the skin or the joints so their material should be fracture, temperature, and wear-resistant.

Cost

The cost of your printer resins is very important to make sure that the resins can fit in your budget whereas some of the printer resins available in the market can be very expensive. For most printers, the quality resin will cost you at least $50, but some of the resins can cost you in the hundreds too.

Conclusion the Printer Resin

Printer resin as a material provides far better 3d printing quality as compared to FDM 3D printing material. This better quality came at the high cost of materials and 3D printers. This material is highly recommended for 3d printing parts that are highly complex, need a highly detailed final product, and very high-quality surface finish. A drawback of these materials is that they print very brittle products.

Follow Techdee for more!